Why Bihar is the Center of Makhana Processing

Traditional Makhana Processing in Bihar. Bihar is the undisputed heart of India’s makhana industry. Nearly 90% of the world’s makhana supply originates from Bihar, especially from the Mithila region.

Major processing districts include:

- Darbhanga

- Madhubani

- Saharsa

- Supaul

- Purnia

For centuries, the people of this region have practiced makhana cultivation and processing as a family-based livelihood. It is not just an agricultural activity but a deep-rooted cultural heritage.

Quick Answer:

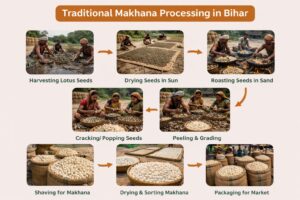

Traditional makhana processing in Bihar involves harvesting lotus seeds from freshwater ponds, sun-drying them, roasting in hot sand, and manually popping the seeds to produce edible fox nuts. This age-old process is mainly practiced in the Mithila region using traditional tools, skilled labour, and indigenous techniques passed down for generations.

Explore more about makhana and its journey from ancient farming to modern superfood::

- History of Makhana – Ancient roots of makhana in Indian culture

- Makhana Cultivation in India – Where and how makhana is grown

- How Makhana is Made – Complete step-by-step process

- Makhana in Ayurveda – Medicinal uses and health benefits

- Makhana vs Other Snacks – Why makhana is healthier than popular snacks

What Makes Traditional Processing Unique?

Unlike modern food factories, traditional makhana processing:

- Uses no chemicals or preservatives

- Depends entirely on human skill and experience

- Preserves nutritional quality naturally

- Supports thousands of rural families

Even today, despite mechanization, most high-quality makhana is still processed using manual methods.

Step-by-Step Traditional Makhana Processing in Bihar

1. Harvesting from Lotus Ponds

Makhana seeds grow inside lotus pods in shallow ponds. Farmers dive into muddy waters and manually collect mature pods — a physically demanding and risky job.

This harvesting season usually happens between:

August to October

2. Seed Extraction and Cleaning

The pods are broken open to extract black lotus seeds. These seeds are:

- Washed with clean water

- Sun-dried for several days

- Stored temporarily before roasting

3. First Sun Drying

Seeds are spread on bamboo mats under sunlight. This step reduces moisture and prepares them for roasting.

Natural sunlight is critical — artificial drying reduces quality.

4. Roasting in Hot Sand (Bhatti Process)

This is the most crucial stage.

Seeds are roasted in large iron pans filled with hot river sand over firewood stoves. The intense heat hardens the outer shell.

This requires:

- Constant stirring

- Perfect temperature control

- Years of experience

5. Manual Popping (Phodai Process)

After roasting, seeds are hit individually with wooden mallets. Skilled workers crack the shell and the inner seed pops open into white fluffy makhana.

This step is entirely manual and cannot be replaced by machines.

6. Final Cleaning and Grading

Popped makhana is:

- Cleaned again

- Sorted by size and quality

- Packed into jute or food-grade bags

Premium grades are exported or sold to brands, while lower grades go to bulk markets.

Tools Used in Traditional Processing

Traditional makhana processing uses simple tools:

- Iron roasting pans (Kadhai)

- River sand

- Wooden mallets

- Bamboo drying mats

- Clay or brick stoves

No advanced machinery — just skill, fire, and patience.

Economic Importance for Bihar

Traditional makhana processing supports:

- Over 3 lakh rural workers

- Thousands of self-help groups

- Entire village economies

It is one of Bihar’s most important agri-based industries after rice and wheat.

Many families depend solely on makhana for:

- Income

- Education

- Food security

Why Traditional Processing Produces Better Makhana

Compared to machine-processed fox nuts, traditional makhana:

- Tastes fresher and crunchier

- Retains natural minerals

- Has better puff size

- Stores longer naturally

- Is safer (no chemical treatment)

This is why premium brands still source from traditional Bihar processors.

Challenges Faced by Traditional Processors

Despite its importance, the industry faces challenges:

- Hard physical labour

- Low mechanization support

- Middlemen exploitation

- Limited branding for farmers

- Climate change affecting ponds

Still, the resilience of Mithila farmers keeps the tradition alive.

The Cultural Identity of Makhana Processing

In Mithila, makhana processing is not just work — it is:

- A family tradition

- A community activity

- A symbol of regional pride

Many festivals and rituals even include makhana as a sacred food.

Conclusion

Traditional makhana processing in Bihar is one of India’s finest examples of heritage agriculture. From lotus ponds to popping mallets, every step reflects centuries of knowledge, patience, and craftsmanship.

In a world of industrial food, makhana stands out as a naturally processed superfood, and Bihar remains its undisputed guardian.

Q1. What is traditional makhana processing?

Traditional makhana processing is a manual method of producing fox nuts by harvesting lotus seeds, sun-drying them, roasting in hot sand, and cracking them by hand to pop the edible seed.

Q2. Why is Bihar famous for makhana processing?

Bihar produces over 90% of the world’s makhana due to its natural wetlands, skilled farmers, and centuries-old traditional processing techniques.

Q3. Which region in Bihar is best known for makhana?

The Mithila region, including Darbhanga, Madhubani, Saharsa, and Supaul, is the most famous area for makhana cultivation and processing.

Q4. How long does traditional processing take?

From harvesting to final grading, traditional makhana processing can take several weeks depending on weather, drying time, and labour availability.

Q5. Is traditional makhana better than machine-made?

Yes, traditionally processed makhana is considered superior because it retains better taste, nutrition, puff size, and has no chemical treatment.

Q6. Is makhana processing done by machines?

Mostly no. Even today, most high-quality makhana in Bihar is processed manually using traditional tools and human skill.

Q7. Is traditional makhana processing eco-friendly?

Yes, it uses natural sunlight, firewood, sand, and manual labour, making it one of the most environmentally friendly food processing methods.

Q8. How many people depend on makhana processing in Bihar?

Over 3 lakh rural workers and thousands of families depend on makhana cultivation and processing for their livelihood.

Q9. Why is makhana expensive?

Makhana is expensive because it requires intensive manual labour, underwater harvesting, slow processing, and skilled workers.

Q10. Is traditional makhana exported?

Yes, premium traditionally processed makhana from Bihar is exported to the USA, Europe, Middle East, and other countries.